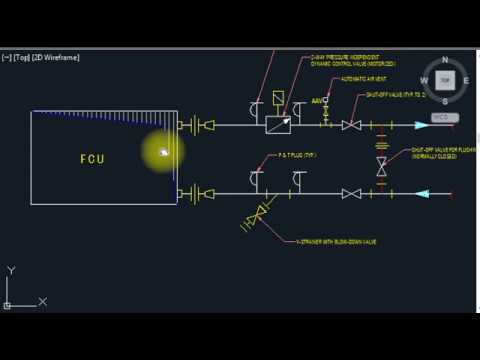

At low loads the chilled water flow through the cooling coil is restricted in response to supply air temperatures to the space but the total quantity returned to the chiller remains constant.

Chilled water fan coil unit valve arrangement.

20 000 btu blow through chilled water fan coil unit with motorized valve 300 cfm to 1 200 cfm.

Fcus can be wall mounted freestanding or ceiling mounted and may be concealed in ceiling voids.

Chilled water schematic and condenser water schematics.

In this article we l be covering chilled and condenser water schematics to learn how to read them how to identify the main components and symbols as well as real world examples additionally we ll cover the purpose of the main components and different design types.

Product lineup page unit model coil rated esp esp range 3 appication power supply page 4 fww vc 2 pipe 3 rows 12 30 50pa 0 70pa 220 240v 50 hz ac.

More importantly daikin boasts the most complete fan coil series and realizes product experience covering units valves and controls.

Reasons for using this technology.

Our chilled water fan coil units vary are offered in the range of 1 0 to 2 5 tons with dx chilled water or heating coils for cooling heating purpose the units can be either placed on the floor or suspended from the ceiling.

Explosion proof marine fan coil unit make up air.

Chilled water fan coil units.

The room temperature is controlled by a controller connected to the picv actuator.

9 000 btu left side discharge chilled water fan coil unit with motorized valve and electric heat.

Typical 4port control valve arrangement for lthw chilled water to fan coil unit utilising dominator z3000.

Where fcus are supplied with chilled water and hot water from central boilers and chillers they are generally referred to as two pipe either heating or cooling or four pipe both heating and cooling units.

A control valve installed on the return pipework would be controlled by a standalone thermostat or a building management system bms.

The control can either be modulating or on off depending on the system layout.

A 2 position water control paddle style valve driven open with spring return bypass upon a call for heating or cooling to maintain space temperature.

Fast installation saving in time manpower on site.

Fan coil unit application with picv control.

The cooling coils are made of copper tubing and sine wave aluminum fins with vent valve for air removing.

It is easier to use for customers.

Energized the bypass port is blocked and water can flow through the unit s water coil to heat or cool the space depend ing on the supply water temperature.

Recommended installations pressure independent control.

If you think all video information are worth for you just have to pay for coffee to support channel https www paypal me afreenali hvac fcu fan coil unit.